The 2021 United Nations Climate Change Conference (COP26) has ended on a positive note. There were some wins and losses (Figure 1) and we can continue to debate if the climate summit was a success or a failure.

However, there must be continued corporate actions to mitigate our carbon footprint and emissions and to push on with the sustainability journey. In the last few articles, we have articulated why sustainability is now a “must have” though the top drivers for sustainability vary widely, from a focus on growth opportunities, to green investment, to improved productivity.

Since the onset of the COVID-19 pandemic, one particular area many people have paid close attention to is sustainability in the supply chain. There is a global trend of consumers doing more of their shopping online, where many have begun to seek out information about companies’ environmental and social practices even before purchasing new products. In addition, the extreme weather events that climate change experts have predicted has become a reality. Mass media has also reported a series of supply shocks highlighting the complexity and fragility of organisations’ supply chains. Still, there are many leaders and companies that are struggling to balance their long-term goals for sustainability with the short-term need to get products out to customers.

The focus on sustainability stems not just from how important it is, but also how hard it is to execute a sustainability strategy well. Leaders want their companies to be more sustainable, but with supply issues, cost pressures, and other fast-changing circumstances, they have not been able to pursue sustainability goals while meeting the profit pressures demanded by their shareholders.

One area that corporates can focus on is their supply chain processes which are often the biggest contributors to a company’s overall carbon footprint. The sustainability of supply chain requires more than the actions taken by just one company. The corporate’s suppliers—and its suppliers’ suppliers—are key to its ability to achieve sustainability targets. In the past, consumers cared about corporate sustainability and social responsibility, but now they are much more aware of how supply chains impact these factors.

A company’s distribution network design provides a valuable opportunity to improve sustainability, while reducing costs and achieving faster deliveries. Ideally, companies should have a holistic programme that assesses location optimisation, estimates life-cycle energy savings, coordinates source and demand points, and accounts for reverse logistics.

When it comes to these types of distribution networks, some industries are slightly ahead. For instance, in the petrochemical industry, environmental impact is already top of mind for consumers and regulators, which can lead to broader adoption of carbon reduction efforts. Some companies have started integrating carbon reduction programmes into their overall distribution strategy to expedite implementation. These initiatives can also align carbon reduction goals with broader business goals related to costs and efficiency.

Hence it is noteworthy that some of the world’s largest companies have set forth bold plans to make their supply chains more sustainable. For example, Unilever and Cargill have both pledged to make their supply chains deforestation-free.

Meanwhile, consumers’ demand for more sustainable supply chains is translating into political action as governments introduce new regulations and enforcement processes targeting environmental, people and social impact. For example, the US Customs and Border Protection has ramped up enforcement of import restrictions on companies whose supply chains incorporate child and forced labour.

Taking Action

To tackle sustainability, corporates should consider it just like another business challenge. The approach should be the same as for other challenges: define the strategy, execute the process, define roles and responsibilities, and select tools and approaches.

A process could include the following key points

1. Document the organisation’s definition of sustainability and its high-level sustainability strategy.

2. Define ownership for sustainability within the organisation. For example, will sustainability be owned at the global, regional or local level? Will supply chain have a seat on an enterprise-level governing board? Will it be owned at the supply chain functional level or by those who own parts of the supply chain such as planning, sourcing, procurement or logistics?

3. Deploy and strengthen processes to ensure transparency with suppliers, monitor global disruptions, prevent behaviours that introduce risk (e.g., maverick purchasing) and provide employees with the knowledge they need to make sustainable decisions.

4. Assess sustainability factors within supply chain processes. For example:

- Within supply chain planning, consider how network design can be optimised for sustainability;

- Within sourcing and procurement, evaluate supplier diversity and supplier risk/sustainability;

- Within logistics and warehousing, examine carbon emissions, fuel, and routing; and

- Within manufacturing, evaluate carbon emissions, water, and electricity usage.

Each company’s sustainability challenges are different; therefore, each will have different objectives and different approaches to reach those goals. Some companies may need a complete overhaul of their environmental, people, social and governance practices. However, organisation leaders should remember that sustainability goals need not conflict with financial and customer service priorities, especially when those priorities are established with a long-term point of view.

A focus on processes and embedding measures within those processes enables corporates to track progress and to demonstrate how they are working towards their commitments. With this approach they can 1) pinpoint the right inputs, outputs, and choices/options; 2) empower employees to make sustainable decisions and informed trade-offs; and 3) collect metrics to know what worked and what did not.

Regular updates to processes in the high-impact area of supply chain, and logistics in particular, can create repeatable, consistent improvement with regard to sustainability.

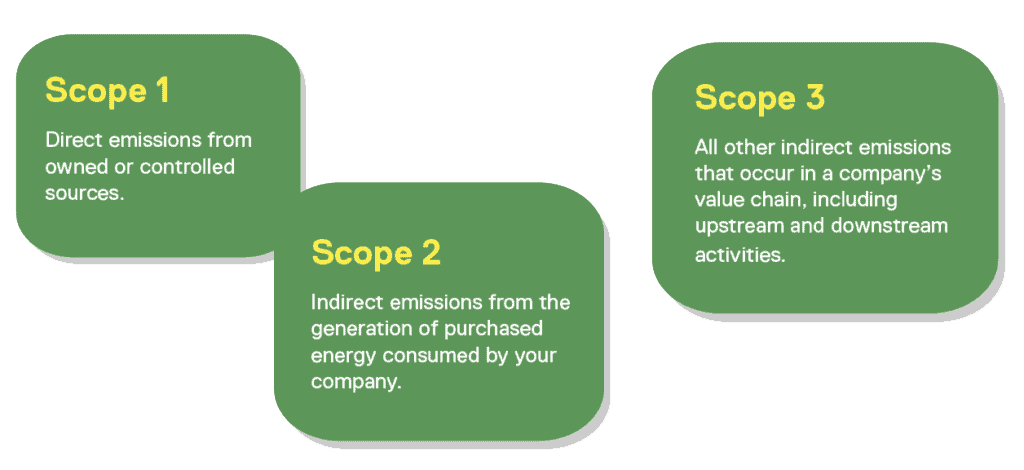

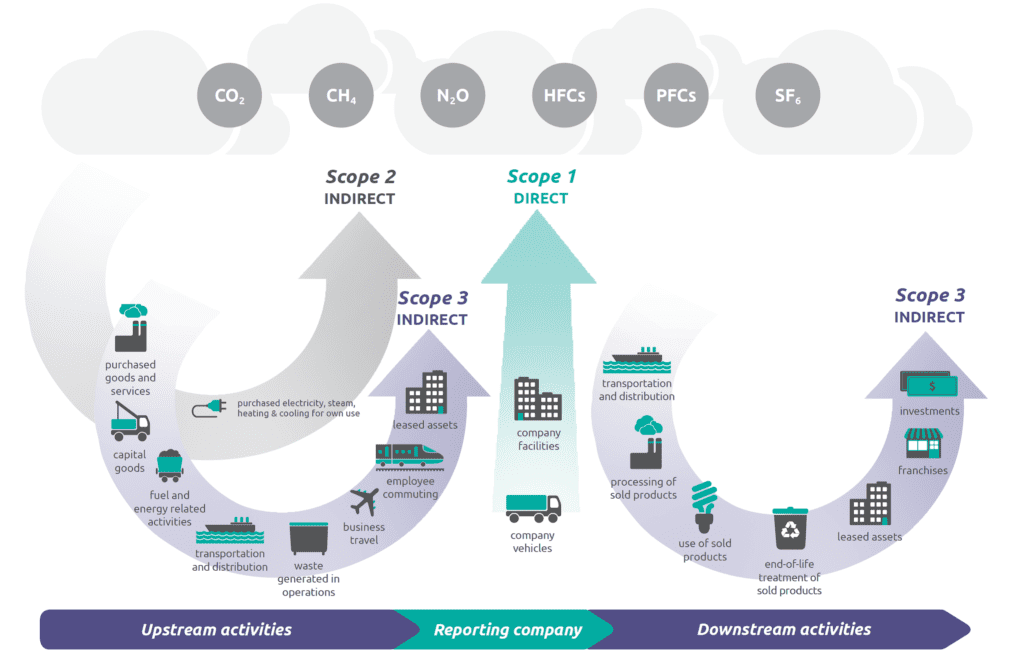

Under the Greenhouse Gas Protocol Corporate Standard, emissions can be classified into three scopes.

According to a sustainability-focused media company, edie, most companies report that 80 per cent of their emissions fall under Scope 3. Much of Scope 3 is comprised of supply chain activities such as distribution and transportation, as this illustration from the Greenhouse Gas Protocol shows (Figure 2).

The key to tackling emissions is bringing process to bear on sustainability, which helps turn commitments and promises into action. When it comes to meeting the challenge of sustainability, any organisation that has experience applying a process-first approach to other business challenges—like digital transformation and M&A—will be at an advantage. In a nutshell, in order to change your business for the better, you have to know your business operations intimately and measuring and profiling its carbon footprint is the first step.